Surindera Cycle Pvt Ltd. Ludhiana, is a renowned name among the manufacturers of bicycles and bicycle components. The company started its business in 1990 with the manufacturing of high quality chain wheel and cranks.in 1993, the company started manufacturing Bicycle handle bars as well in a short span of 25 years, the company has increased its production in chainwheel to become largest manufacturer of bicycle chainwheel in India. To stay ahead of the competition, the company planned a massive upgradation in technology as well as in the product line in 2011. Thereafter,, shortly the company started production of high end chainwheel as well.

Surindera Cycles Pvt. Ltd. has the distinction of installing 6 complete hot forging plants. 1 cold forging plant. 28 VMC Machines and fully automatic 2 GLYDO Nickle chrome plating plant, Semi Automatic Acrylic ED Plant. The company has state of the art technologies like Hot Foring Plant, Machining centres, Power Presses (10 MT to 600 MT2 SPM for Sheet Cutting (1500 Tans each) and Automatic Assembling (SPMS) besides modern finishing plants.

At present, the company is the largest manufacturer of chain wheels, cranks and handle bars in India. The com-plying is executing supply of its products to major OEMs throughout India and also exporting a sizeable production to South East Asia and Africa. The company is leading ahead to scale new heights of production and marketing excellence.

To ensure qualitative growth of its products, the company is equipped with a specialised Research and Development department. It has also included an experienced team with facilities like CNC Vertical Machining Centre, EDM, Elaborate Tool Room for all kinds of dies and 5 axis CARBIDE tool Manufacturing facility. All kinds of testing facilities have also been developed at the company premises. The company is also equipped with a dealer network and after sales service arrangements for its entire patrons and customers.

The company has also been awarded a coveted ISO 9001:2015 Certified by TUV Rheinland with positive thinking of management.

Commitment to achieve our Vision through our Core Value and to provide our customer's optimal solutions at the lowest operation cost,there by achieving customers' satisfaction, growth & success."

To be recognized as the unparal-leled market leader in providing superior products and exceptional after-sales support.

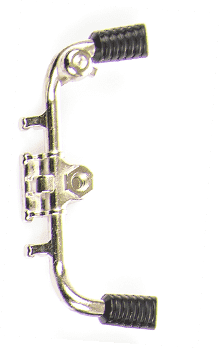

Nickle Crome

Plating

Powder

Coadting

Plastic

Injection

Moulding

Acrylic

ED Coadting

Nickle Crome

Plating

Powder

Coadting

Plastic

Injection

Moulding

Acrylic

ED Coadting